Our Machines

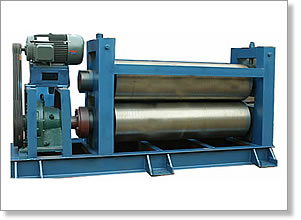

The Machines are designed for production of expanded metal sheets with the thickness of 0.5mm - 8.0mm and the maximum width of 2000mm. Metal plates processed include Stainless Steel, Carbon Steel, Aluminum, Nickel, Titanium as well as other materials. The shearing force of the expander is related to the thickness of the materials as well as the LWD. Considering the same thickness of the raw materials, the shearing force will increase with the decreased LWD.

The expanded metal production line covers machinery for sheet metal expanding, pressing, flattening, shearing and slitting.

- Bearing Transmission: Light load, low noise (replacing the traditional bush)

- Alloy roll: Long life, good quality flat finish

- Easy maintenance

- Automatic shutdown for energy: Reduction of labor cost.

- Spindle speed: 420 r / min.

- CNC brake function: Automatically brakes.

- The entire NC program in computer [PSC] control to ensure the quality of flattening

- Pulley portion: The flattening rolls can be adjusted up and down.

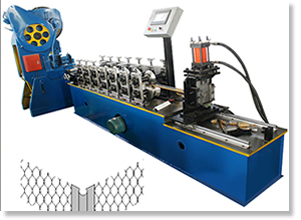

The machine is designed for producing sheet metal screen with holes of different shapes in different materials. The production line consists of punching machine, feeding machine, decoiling device and other auxiliaries.

The metallic material for punching: Iron plate, stainless steel plate, aluminum plate, galvanized plate, nickel, etc.

Nonmetallic material: Fibre plate, plastic plate, vinyl, etc.

Corner beads Machine

Corner beads Machine

Main Parameters:

1: Installing SIze: 15000x1100x1700mm

2: Total Net Weight: 2400kg

3: Cotroller: Relay Control

4: Total Motor Power: 10.2 kw

5: Speed: 10-18000 mm/min

MAIN PARAMETER:

1: INSTALLING SIZE: 15000mm x 1100mm x 1700mm

2: TOTAL NET WEIGHT: 4850kg

3: CONTROLLER: BY RELAY

4: TOTAL: 13.2 kw POWER OF EXPANDER: 5.5 kw

GROOVE MAKING POWER: 5.5 kw HYDRAULIC CUTTING SYSTEM: 2.2 kw

5: SPEED: 0-2000 mm/min